Breathable Garments with Thermo - Physiological Wear Comfort - A Review- Juniper Publishers

Journal of Fashion Technology- Juniper publishers

Abstract

Thermo physiological wear comfort concerns with the heat and moisture transport properties of clothing and the way it helps the clothing to maintain the heat balance of the body during various level of activity. Hence, heat and moisture transfer analysis for clothing and fibrous materials is an important issue for the technological developments and scientific understandings. Continued advances in textile processing technology, the growth of application of nanotechnology have resulted in a wealth of research in order to characterize the behavior of these materials. This paper systematically reviews the recent research on thermo responsive polymers, applications in the field of textiles and development of thermoregulatory breathable garments. The moisture transport properties and various factors affecting it are also discussed. More on that, the limitations of conventional breathable fabrics are overcome by redesigning the textile material surface, operating at a microscopic level using Phase Change Materials (PCMs), Shape Memory Polymers (SMPs), Biomimetics and many more, in the form of smart technology that facilitates active comfort to the wearer are also discussed. The reported testing methods and parameters used for determining heat and moisture are summarized. This article describes the need of heat and moisture transmission in clothing, desired attributes for heat and moisture management and parameters affecting heat and moisture transmission in clothing.

Keywords: Thermoregulatory garments; Phase Change Materials (PCMs); Smart technology

Abbreviations : PCMs: Phase Change Materials; SMPs: Shape Memory Polymers; WVTR: Water Vapour Transmission Rate; WHO: World Health Organization

Introduction

Clothing is an important interface between the human and the environment. Apart from the cultural meaning of clothing it provides insulation against cold, protection against the sun, wind or rain as well as protection from other environmental hazards (chemicals, mechanical). The effect of clothing on thermoregulation depends on the textile materials used. Clothing comfort is determined by a number of clothing properties that affect the thermal conditions at the skin. Skin temperatures and the tactile sensation of the skin (e.g. sticky moist clothing) are the main signals that are fed to the brain and lead to an overall sensation of comfort or discomfort. According to the WHO (World Health Organization) criteria, the internal temperature should be kept between (37±1) °C to make the human organism function normal.

Impacts of clothing

Generally, human thermal comfort depends on combinations of clothing structure and chemical nature of fibers, external conditions and factors related to wearer. Thermal comfort of a clothing system is associated with thermal balance of body and its thermoregulatory responses to the dynamic interactions with the clothing and the environment. Thermo physiological wear comfort concerns with the heat and moisture transport properties of clothing and the way it helps the clothing to maintain the heat balance of the body during various level of activity. Heat and moisture flow through clothing is a complex phenomenon. So, heat and moisture transfer analysis for clothing is an important issue for researchers. To create a comfortable clothing a designer considers fashion and other technical factors, fibre nature and size (micro fibres that have particulars properties), surface modification of fibres (hydrophobic or hydrophilic treatments), hydrophobic (GortexR) or hydrophilic membranes fused to the textile layers, weaving or knitting patterns and abrasion of the fabric surface are parameters by which we can enhance comfort of clothing. Extensive research has been published in the literature on the diverse aspects of simultaneous heat and moisture transfer both theoretically and experimentally. Results shows, that the ability of clothing materials to transport moisture vapour is a critical determinant of wear comfort, especially in conditions that involve sweating. So, for satisfactory performance of clothing comfort researchers recognize that clothing comfort has two main aspects. These are thermo physiological and sensorial comfort. The first relates to the way clothing buffers and dissipates metabolic heat and moisture, whereas the latter relates to the interaction of the clothing with the senses of the wearer, particularly with the tactile response of the skin, which includes moisture sensation on the skin. The wear comfort of clothing is affected by physical processes include heat transfer by conduction, convection and radiation, meanwhile, moisture transfer by diffusion, sorption, wicking and evaporation. During higher activity level and/or at higher atmospheric temperatures sweat gland get activated which produce liquid as well as perspiration. When the perspiration is transferred to the atmosphere it carries heat (latent as well as sensible) thus reducing the body temperature. The fabric being worn should allow the perspiration to pass through; otherwise it will result in discomfort. If moisture transfer rate is not adequate during sweating than it may result in heat stress due to increase in rectal and skin temperature. From last few decades the field of dynamic heat and moisture transport behaviour of clothing and their influences on clothing comfort are main interest of researchers.

Thermal insulation

Clothing by its nature has an insulating effect and resists transfer of excess heat and moisture from the body. A still layer of air confined between the skin and fabric or between two fabric layers can make the wearer extremely uncomfortable due to its barrier effect. Thus the most important purpose of clothing is to provide a stable microclimate next to skin by maximizing the rate of heat and moisture loss from the body. If ratio of evaporated sweat and produced sweat is very low, moisture will be accumulated in the inner layer of the fabric system, ultimately affect the thermal insulation of clothing. It means there is some correlation between heat and moisture transmission through fabrics, which play a major role in maintaining a wearer's body in comfort zone. Hence a clear understanding of heat and moisture transmission from clothing is required for designing new high performance fabrics for different application. Clothing thermal insulation is described as the resistance to heat transfer by convection, radiation and conduction. It is determined by the properties of fiber materials and fabric construction, the layers of trapped air in the fabric and the air layers between fabric layers [1]. The most important factor is the thickness of trapped, still air layers, because the air is known as one of the best heat insulator [2].

Studies examining thermal comfort properties of fabrics

Typically, fabrics do not inherently provide thermoregulation. Their thermo-regulation is affected by not inhibiting or rather supporting the thermo-regulation efforts of the body itself. The role of the fabric will be to allow air to circulate around the body and at the same time provide a cushion of insulation (either hot or cold) when the body needs it. The fabric must be able to adjust to the needs of the body over a wide range of external temperatures and activities. Certain combinations of fabric construction, chemical finishes and garment construction can also keep the body warmer or cooler, depending on the environmental conditions. Usually fabrics are geared for one or the other. Cold weather garments must address both radiant and convective heat loss. On the other hand, warm-weather garments must aid evaporative heat loss by increasing moisture movement, and increasing the velocity of heat conduction through the material. Control of airspace in the microclimate between the skin and the garment, or between layers is of prime importance.

Breathability/Moisture management

The absorption and retention of water must be as close to zero as possible and there should be a mechanism to ensure that the moisture is moved away from the skin. One of the basic functions of clothing is to protect human body from the effects of climate change and to support its own thermoregulatory functions in various combinations of environmental conditions and physical activity. The microclimate around the body - it is an interaction of parameters, such as: skin temperature, humidity and air motion. The values of these factors depend on the amount of heat produced by the body and the conditions of heat exchange with the environment. Clothing works as a barrier for the transport of heat and water vapour between the skin and the environment. This barrier is created by:

a. Clothing layers,

b. Air contained between the layers,

c. Air inside the materials.

New fabrics and designs have been introduced with the purpose of improving thermoregulatory properties. The latest manufactures innovation is clothing with integrated channels into synthetic fabric. These channels are proposed to move the moisture away from the body and increase evaporation qualities. If inner and outer channels work, it might offer additional cooling properties which might lead to lower body heat storage and improved performance [3].

Clothing for thermoregulation

The thermoregulatory clothing depending on the level of their “intelligence” of thermoregulation function integrated into textile, respectively, ability to respond to environmental parameter changes.

Active versus Passive Thermoregulation: The functional activity (sense - react - adapt) of smart textiles can provide active comfort regulation function to textile materials. Based on the ability to respond to environmental parameter changes, textiles with thermoregulation function can be divided into passive and active. Passive thermoregulation is present in conventional textiles (eg, silk or wool) which are able to warm or cool depending on environmental conditions. It can also be achieved with textiles made of special fibres (eg, hollow fibres for warming) or with a special textile structure (eg, three- dimensional-structure constructions), as well as with functional multilayer clothing systems (eg, first layer with good vapour and air permeability, second layer with warmth isolation, third layer with protection from environmental conditions such as wind and rain).

Active thermoregulation is the property of smart textiles which can respond to changes in ambient temperature to keep balance in human body microclimate temperatures. Breathable coatings for textile fabrics usually maintain fabric permeability towards air and moisture in addition to other functionalities, depending on their end uses. Coating materials can be permeable, smart, waterproof, etc., which in turn are influenced by polymer, specialty chemicals, additives, process aids, and many other chemicals necessary to produce the specified customer properties of the quality standards and durability demanded [4].

o In the 1970s, WL Gore introduced GoreTex, material which had a high standard of water resistance combined with a high level of breathability. Gore-Tex® is a thin film of expanded PTFE polymer claimed to contain 1.4 billion tiny holes per square centimetre. PTFE polymer can also be used as a coating on textile substrate [1].

o Polyurethane coatings are used in wide applications such as apparel, artificial leather, fuel & water storage tanks, inflatable rafts and so on, owing to several advantages over other polymeric coatings, such as low-temperature flexibility, softer handle, very high tensile, tear, and abrasion resistance. PU has been widely used to prepare microporous films and coatings [5].

o There are various commercial PU-based breathable microporous films:

o Entrant made by Toray Industries and Porelle by Porvair are microporous films and coatings made from PU.

o Permatex launched by J.B. Broadley is a PU-based film designed for either transfer coating or laminating fabrics, or it may be used separately as a drop liner

o Tarka, a microporous PU film, is produced by Acordis (formerly Courtalds) and is applied by a transfer process from the release paper [6].

o Aluminium-coated PU nano webs have also been reported for improved thermal comfort and waterproof breathable performance.

o The two-phase morphology of PUs (consisting of soft and hard segments) allows its properties to be varied widely according to end-use application. The hydrophilic segment can be introduced into hydrophobic PU and can be made breathable [7,8].

o Sympatex polyester film material introduced by Akzo is a hydrophilic membrane in which polyether groups were incorporated to impart hydrophilicity.

o Most highly hydrophilic polymers such as cellulose, polyvinyl alcohol, and polyethylene oxide are water soluble and/or too stiff and inflexible for use as coatings on fabrics. Conversely, most nonporous polymers are too hydrophobic to be breathable. However, there are some polymers such as silicones and their blends with PU, some acrylics, and little one-component PUs that lie somewhere between these two extremes [9]. Several other coatings primarily based on PUs, PTFEs, acrylics, polyacrylamide, polyvinyl alchohol and polyamino acids are produced by various manufacturers [10].

o The ADVANSA ThermooCool™ combination is a unique blend of fibres with a hollow core along with fibres with a channelled surface providing benefits beyond what can be expected by just one type of fibre in a single yarn. It protects the user from temperature changes. This also prevents post exercise chill and still allows excess heat to dissipate into the air Wearing these garments helps to keep the body at a comfortable temperature whatever the outside temperature or the physical intensity of your exercise. Without any kind of chemical treatments, ADVANSA ThermooCool™ fabric provides enhanced comfort coupled with moisture management during physical exertion hollow fibres gives a thermo buffering capability that reduces extreme temperature changes on the fabric helping to keep users in the Comfort Zone [11].

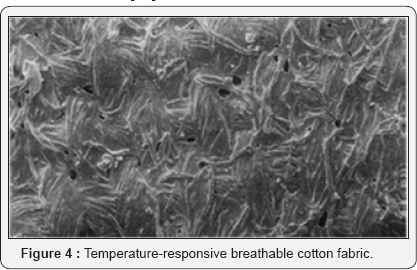

Smart technology

By redesigning the textile material surface, operating at a microscopic level, new added-value textile material can be created by smart coating. It can be use of conventional textile fibres and, by modifying a very thin surface layer of the material, to create modern smart textile materials that not only keep us warm, dry, and comfortable but are expected to react and interact with a wide range of stimuli and situations. Facilitated by technological advances in smart coatings, active comfort regulation by smart textiles and clothing has expanded rapidly, providing the specific needs. These fabrics restrict the loss of body warmth by stopping the transfer of vapour and heat at a low temperature, and transfer more heat and water vapour from inside to outside at high-temperature applied SSP copolymer poly (N-tert-butyl acrylamide-ran-acrylamide: 27:73) with 1,2,3,4-butanetetracarboxylic acid (98%) as a cross-linker and sodium hypophosphite as a catalyst on cotton fabric using a knife-over-blanket arrangement to produce temperature- responsive breathable fabrics [12-14].

Shape memory polymers

Fabrics coated with Shape Memory Polymers (SMP) are termed smart breathable fabrics and act as a switch to control the transmission of water vapour. At lower temperatures, the coating substance on the fabric exists in a swollen state (by absorbing water from the surroundings), which results in the closure of microcracks. At a temperature higher than the transition temperature, the coating exists in a collapsed state (owing to the predominance of hydrophobic interactions), which results in opening of the micro cracks. Another result is diffusion flux, which is governed by changes in both the diffusion coefficient and the diffusion path of water molecules through the swollen and collapsed coating [15-18].

Phase change materials (PCM)

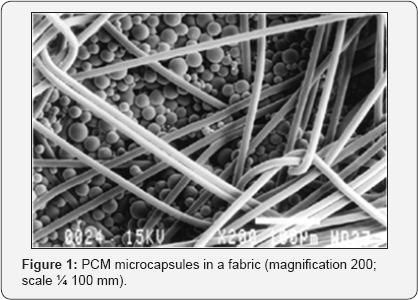

Regarding the type of PCM material, hydrated inorganic salts, linear long chain hydrocarbons, polyethylene glycol, and paraffin wax (octadecane, nonadecane, hexadecane, etc.) can be encapsulated on textile materials. The preferred PCMs for textiles are n-paraffin waxes with various melting and crystallisation points according to their carbon numbers. Octadecane is particularly suitable for clothing because its melting point is about 28.2 °C and it absorbs a large amount of heat and releases that heat in a slush state, which is below the mean skin temperature of 33.3°C ©Outlast Technologies LLC are another class of smart textiles useful for making breathable fabrics. Phase change process is the change of material physical state from one state to another like solid to liquid and vice versa. PCMs are enclosed in small plastic spheres with a diameter of only a few micrometres, known as PCM microcapsules (Figure 1). They are permanently embedded in either the fibres/PU foams/coated on the surface of a textile structure. PCMs absorb heat energy as they change from a solid to a liquid state and release heat as they return to a solid state. By careful selection of the PCM, the fabric can act as a transient thermal barrier by protecting the wearer from the effect of a cold or hot environment within limited temperature conditions. When a sudden change in ambient conditions occurs, PCM fabrics delay the transient response and decrease body heat loss. Fibres, foams and fabrics with PCM microcapsule treatment are widely used today in garments such as ski suits, gloves, socks, sweaters, boots, protective garments and shoes to improve thermo physiological wear comfort in cold climate [19-21].

Fabrics based on biomimetics

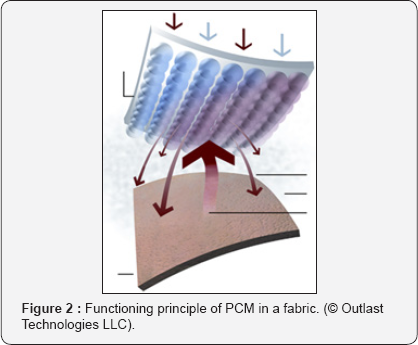

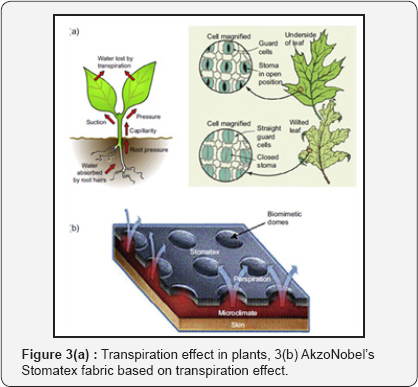

Biomimetics is the mimicking of biological mechanisms, with modification, to produce useful artificial products. There is potential to improve the vapour permeability of fabric coatings by incorporating an analogue of the leaf stomata, which opens when the plant needs to increase moisture vapour transpiration and closes when it needs to reduce it. AkzoNobel is marketing the product under the trade name of Stomatex. This is a closed-foam insulating material made from neoprene incorporating a series of convex domes vented (©Outlast Technologies LLC) (Figure 2). These domes mimic the transpiration process that takes place within a leaf, supplying the controlled release of water vapour to provide comfortable wear characteristics (Figure 3). Stomatex is claimed to respond to the level of activity by pumping faster as more heat is produced, returning to a more passive state when the wearer is at rest. Stomatex is used in conjunction with Sympatex [22-24].

Moisture Permeability-Adaptive Fabric

A new type of intelligent fabric with thermal and humidity managing ability was developed by combining with thermo- responsive polymers. When the ambient temperature is high, the formerly swollen polymer films on the fabric surface will switch to the collapsed state. Thus numerous pores form in the thermo-responsive polymer films, leading to the increased flushing of water and heat exchange (Figure 4). Conversely, the water flow is blocked by the “off” state of the pores due to the swelling of the hydrogels. Usually, the water permeability is corresponding to the heat storage and loss. Therefore, the temperature-sensitive polymers on the textile are regarded as moisture and thermo-controlling system, which can be used to make high-performance apparel such as anti-soaking diving suits. Comparing to the conventional wet suit, it can protect the divers from cold hazards and keep warm in cold water [25].

Characterization of thermo-responsibility

Wettability: Contact angle is the angle of liquid/vapor interface on a solid surface. Wettability of surfaces is influenced by two key parameters: the surface chemistry and roughness. The former one was characterized as an important indicator for the success of functionalization. With increasing temperature the contact angle of surface modified by polymers will have a sudden increase. On a smooth surface, the water Contact Angle (CA) increased about thirty degrees. This phenomenon can be explained by the switch between inter- and intramolecular hydrogen bonding.

Water uptake

The specific volume change of thermo-responsive textiles is expected to control the water uptake. Thus, the liquid management ability is correlated to capability of responding to temperature signals. The relationship can be revealed by studying the swelling/de-swelling or hydration/dehydration kinetics [26].

Air/Moisture permeability

Moisture permeability is an important criterion to evaluate the thermo responsiveness capability. For thermo-responsive textiles, the moisture permeability is not present continuously, but it could be activated “on demand” by sensing the temperature change in the local environment. When the temperature is high, the smart fabric displays as normal cloth with open interspaces having good air and moisture permeability. As temperature falls, interspaces are sealed to resist moisture transmission. Water Vapor Transmission Rate (WVTR) measurements can be performed according to the standard UNI 4818-26 or ASTM E96- 80 [27].

Fabric Performance Evaluation

Since the thermo-responsive polymer functionalized fabric is aimed as consumer product, the characteristics of the material in production and use, such as comfort, safety, durability, and mechanical strength, are of vital importance.

Softness/Stiffness

The stiffness is defined as the ability to resist the bending of fabric. And the softness is used to evaluate the opposite characteristics, which is one of the most important properties of fabric. The evaluation of fabric hand can be also guided by AATCC protocols [28,29].

Conclusion

High performance characteristics of apparel are achieved by using innovative technologies. Apart from improving different product properties, innovative technologies incorporate new functionalities with high importance for consumers, with the ultimate goal of improving comfort, increasing protection, and enhancing performance in human activities. To reach these goals, innovative fibres and fabrics, including high-performance and high-functional fibres, smart and intelligent textiles, and coated & laminated textiles have to be used. Consumers will pay more for garments with both functional performance and style appeal, facilitating to gain considerable competitive advantage in their field. The future approach will be focused on fulfilling multifunctional requirements including friction reduction, high strength, elastic recovery, lightness, wind and water resistance and wear comfort along with other characteristics depending on the climatic conditions and physical activity, to develop enhanced performance products.

Conflict of Interest

The authors report no conflicts of interest. The authors alone are responsible for the content and writing of the paper.

Comments

Post a Comment