Silk Fibroin and its Application in Tissue Engineering - Juniper Publishers

Journal of Fashion Technology- Juniper publishers

Abstract

Due to the special luster, good air permeability and moisture permeability, comfortable wearing, delicate and smooth feel, silk fiber is wildly used in textiles. Recently, with the careful study of the composition, microstructure and physicochemical properties of silk, the application of silk has gradually extended to food, biomedicine, industrial raw materials, environmental protection and other fields. This paper gives one short introduction of silk’s application in tissue engineering.

Keywords: Silk worm; Silk fiber; Silk fibroin; Tissue engineering

Introduction

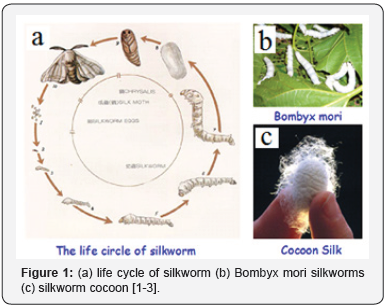

Silk industry is an important support of national economy in China. Recently, silk is affected by reduction of farmland, shortage of labor, and low added value of the products. Developing the versatile silk industry and increasing the added value of silk are the ways to achieve the transformation, upgrading and sustainable development of silk. Figure 1 shows the life cycle of the silkworm. It can be seen from the diagram that after hatching from eggs, silkworms begin to spin and cocoon after five stages of growth and maturity, and then become moths after cocooning. At the end of the fifth instar silkworm, a large amount of raw silk is expelled from its pair of silk glands (Figure 2 (A)) and gradually forms a cocoon. Raw silk is composed of two parallel sericin-coated silk fibers [1-7] (Figure 2 (B)). After silk degumming, the obtained silk fibroin fiber has a bright pearl-like luster and a soft feel, which is very popular in the textile industry. In addition, silk fibroin fibers are widely used in many fields because of their unique mechanical properties and flexibility, biocompatibility, biodegradability and thermal stability [8].

Silk Fibroin’s Application in Tissue Engineering

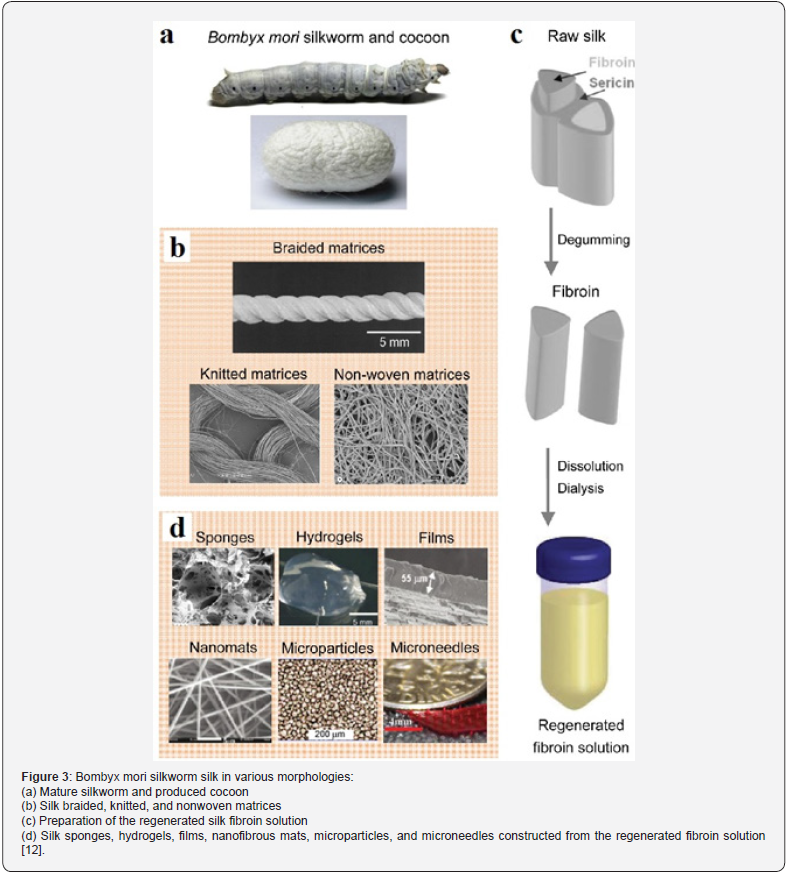

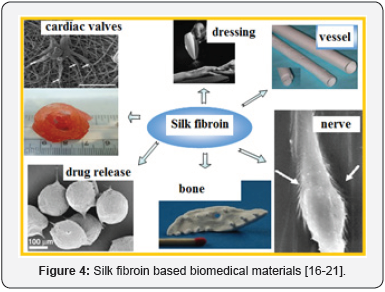

Silk fibroin fibers can be prepared into conventional textile products such as woven, knitted and non-woven fabrics as shown in (Figure 3 (a)&(b)), and regenerated silk fibroin solutions (Figure 3 (c)) can be obtained by degumming and dissolving the silk fibers. By various preparation methods, various kinds of silk fibroin materials with different morphologies and structures can be obtained (Figure 3(d)), such as porous scaffolds, gels, films, nanofibers, microspheres, microneedles and other silk fibroin materials [9-15]. Based on the excellent biocompatibility of the above-mentioned silk fibroin and their various structural forms, silk fibroin is widely used in biomedical fields as shown in (Figure 4), such as vascular scaffolds [16], nerve regeneration [17], bone repair [18], drug release [19], heart valve [20] and skin regeneration [21]. Due to its unique mechanical flexibility, optical properties, biocompatibility, biodegradability and other characteristics, researchers are exploring the possibility of silk fibroin as a flexible electronic for biomedical application.

Comments

Post a Comment